Although they may be small, carbon brushes have a profound effect on the operation of your electric motors, generators and many other types of electrical machinery. Mostly innocuous, these parts are critical because they act as conductive links to let electrical current flow from stationary wires to rotating components. Job categories specifically which generally require zero human presence most of the time, and this across all industry viz transport/maintenance to manufacturing/production incl. in green energy solutions etc Carbon brushes are not something many people remotely consider but they turn to be crucial elements in our contemporary environment.

Specifically, high-performance carbon brushes also find attention as they can seamlessly stand the test of extreme operating conditions while spurring on efficiency and additionally reducing environmental footprint. The application-specific brushes (they are typically made with a period of graphite integrated into the tip) have far less friction compared to carbon block - varying wear rates, etc. better heat dissipation etc. Such a performance advantage is especially worth mentioning with respect to conventional carbon brushes.

Graphite brush is used to operate the heart of every electric motor. The components are the main link between stationary and rotating parts, converts electrical energy into mechanical movement. Carbon Brushes in electric motors (with variable loads and high speeds): Carbon brushes form a critical part of the reliability & life span of these machines as they ensure better contact. In these circumstances, having them on hand all the time is critical as well.

Selection of Fir Industrial ApplicationDeciding on the right use carbon brush for industrial area is a clinch as some parameters like motor type: if it may be DC or AC, voltage that will load and rotational speed property; temperature therefore atoperational level. Other such factors include the material that composes a motor's commutator or slip ring, as well as dust and corrosive substances. Under these conditions the best performance is obtained by brushes having certain characteristics which are selected especially to satisfy a given set of operational parameters.

With our suppliers we have developed a new generation of high-performance carbon brushes that contribute to better energy consumption and emission levels for more sustanaibility from the company. The high conductivity and low weight of the advanced designs minimize energy losses during current transport. They are high performance brushes in that they still give reliably steady execution at extremely hot temperatures, thus decreasing cooling requirements along with lessening the output of greenhouse gas emanations from industrial processes.

In the case of heavy machinery, 24/7 running is expected then maintaining carbon brush in a proper way must be considered so that these machinery do not stop out of nowhere and cause downtime. With frequent visual inspections, a maintenance technician can see any signs of wear or misalignment that would cause motor failure if left unattended. Refer to your maintenance procedure and ensure the brush holder is well lubricated, additionally commutator / slip ring needs regular cleaning in order to prevent buildup of debris that can create high resistance electrical paths.

Both their original purpose have somewhat persisted, as well carbon brushes continuing to evolve into a plethora of other modern technological applications. Examples of Carbon brushes are available in use from wind generators on renewable power to rail systems for traction motors that desire consistent electricity and showing the versatility of this weighty advent with carbon. Their ability to perform multiple roles has been deemed too invaluable for pretty much any technological advancement, including those which are essential in both the aerospace and electronics industries.

This has permitted significant evolution to carbon brushes - and the knowledge of this, as well the capability to engineer for it, have made possible advancements in performance that can deliver energy savings and sustainability across a number of industries. Once we have reliable processes in place to discover, extract/ recover and recycle these finite resources--the true blue planet-hackers play the essential role as advance foot-soldiers of technology evolution.

The heart of any good electric motor is a perfectly designed set of carbon brushes. These components serve as an arrangement between static and moving parts, transforming energy into mechanical movement. Carbon brushes are high-performance versions that include graphite mixed with copper or other conductive material: These carbon brushes reduce friction and overall wear rates, while also offering superior heat dissipation compared to their conventional equivalents. These units maintain consistent contact at high speeds and under varying loads, an important trait for the lifespan of electric motors where continuous operation is required in critical applications.

Choosing the right carbon brush for an industrial process necessitates a good knowledge of operational parameters and environmental conditions, on which this is considered. Such factor as type of motor, voltage-current load balance and speed rotation are predetermined together with environment temperature. Additionally, the type of material that comprises your commutator or slip ring and potential dust- or corrosion-forming substances are not to be forgotten. For a thorough review either one with defined qualities: harder for fast operations to hold up under abrasion, softer ones at lower voltages so as not to spark or metallurgically selected brushes designed specifically for lubricity and reduced friction.

Carbon based brush material are essential to minimizing energy loss and reducing emissions by improving the power balance in their movement. With their advanced brush designs and optimized conductivity, AND always weighs less so the energy losses become significantly reduced during current transmission. The ability to maintain high performance at higher temperatures also means they need less cooling for industrial processes, so are more energy efficient and create fewer CO2 emissions. Efficiency: In a direct way, efficient carbon brushes even proof that they are relevant in the green revolution; e.g. carbon brushes have influence for driving ranges of electric vehicles

When it comes to heavy machinery, proper carbon brush maintenance plays an integral role in keeping the equipment running without interruption opping here -->. Visual inspection on a regular basis will help identify excess wear, comm wears unevenly or brush displacement to keep the motor from failing prematurely. Regular cleaning of the commutator/slip ring and lubrication of the brush holder according to recommended practices will prevent build-up, ensuring the best possible contact between components. Scheduled measurements of brush wear mean that poorly-wearing brushes can be replaced before reaching their minimum recommended length, which in turns leads to more even transfer and longer life for the motor components sharing power delivery duties with them.

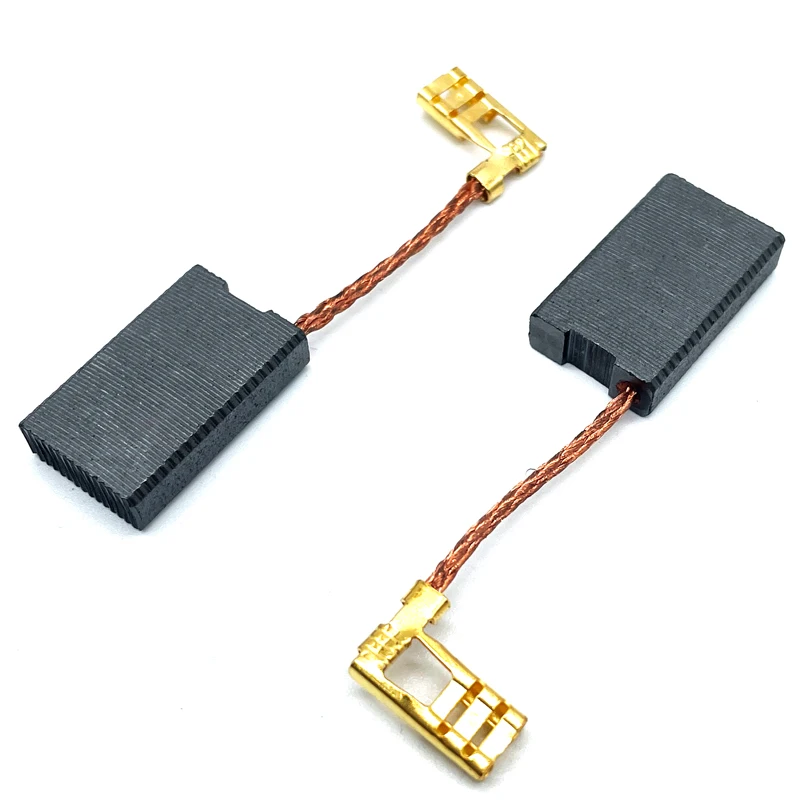

There are over 800 different types of carbon brush suitable for different applications such as carbon brushes for beginners, starter carbon brush assemblies, motorbike carbon brushes, carbon brushes for power tools and household appliance graphite carbon products. Standard size comes from a fully automated production line. keep innovating our products in line with the latest demand on the market. In order to ensure that our mutually beneficial relationship will maximize the profits for our customers.

We have a vast stock of carbon brushes that are popular to meet the B2B demands. We'll deliver small portions from our warehouse. You can leave now and cut down on time.I will arrange to send the products to you as soon as it is possible. We have sold this kind of product to Germany, Spanish.Very efficient carbon brush. From the products to logistical service, secure and fast.

As a company that manufactures carbon brush, we have carbon brush in supplying high-quality products in standard and customized demand specifically for the unique designs, as well as packing demands like box, bag, and the attractive design. Improve the products from every aspect, and make your products more appealing.We are the market leader. Meanwhile, accordingly to your demand, we adjust the quality to make the products in long time working with good price.

More than 20 years expertise in the field We have a carbon brush of various market demands full technical information uninterruptible tests during production quality assurance and go to the every year meet old and new customer keep a good communication with each other Timely replies both before and after-sale sincerity method of business to ensure a long-term cooperation