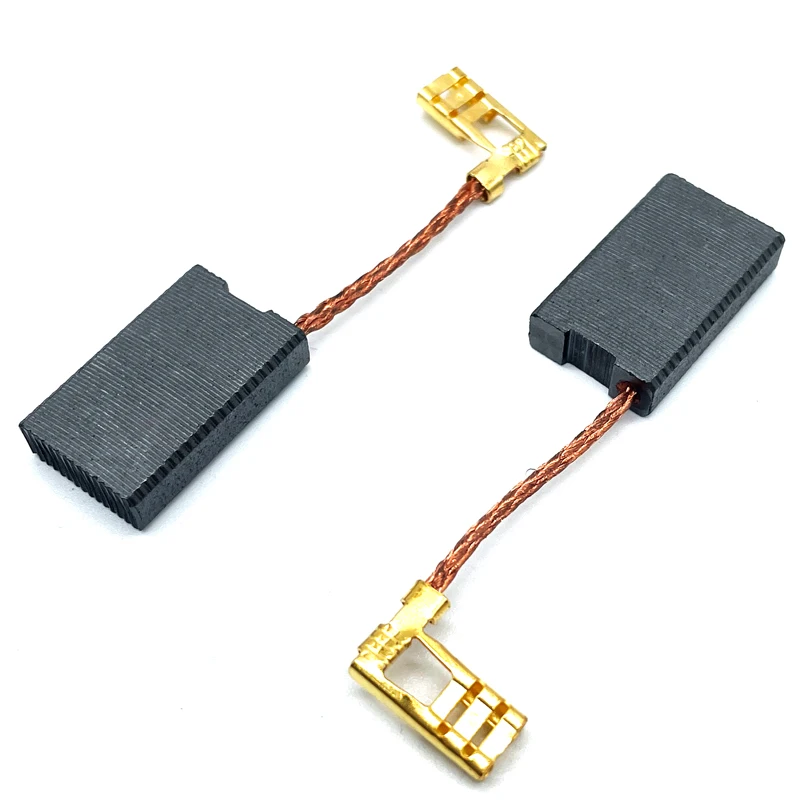

Some examples of this being the carbon brush which is a finished product that can be observed inside an electric motor and do not let their importance go over ones head as they are hidden heros through allowing electricity to flow between stationary parts and moving one due to electrical energy. These are mild but vital bits and pieces, mostly made of graphite as well as metallic elements that allow the electricity to move here between fixed equipment or spinning portions in a dynamo. With the advancement of technology and an over-all effort by all industries to become more efficient as well as longer lasting, knowing about these carbon brushes has never been so important. Next, a closer look is provided on why premium carbon brushes are important and what it does to motor performance with the proper selection guideline, then touch briefly on regular maintenance that should be performed along this way before closing out by looking at some of the newest trends revolutionizing how dynamos deliver their best in both efficiency and lifespan.

Manufactured with the latest materials and techniques, premium carbon brushes are engineered to improve electrical performance and reduce wear. These premium versions are going to be much more than your standard brush, and they will often use some advanced graphite blends that sometimes have copper or silver additives mixed into them so their current carrying ability is improved along with a way for the brushes themselves to dissipate heat. Not only does this eliminate some loss in the system, it also extends both brush life itself and consequently reduces wear on whatever they are making contact with - either commutator or slip ring. The other premium part, brushes are designed to yield electrical losses and allow an energy conversion process that is smooth and efficient as possible.

The quality and compatibility of the carbon brushes also have a direct impact on how well your dynamo performs. Variations in brush hardness, density and geometry have to be optimised for the motor's particular needs during design. Form Example, softer brushes will allow better contact and less sparking in high-speed applications: hard stiff brushes can be preferable for more heavy duty situations that require low speed as the stiffness of the brush allows it to last longer. In addition, the use of advanced surface coatings that are capable to reduce friction and prevent responsible debris from being built up can further improve efficiency and reliability.

Choosing the right carbon brush is an important decision that has a huge impact on how well and long your dynamo performs. A holistic approach requires a combination of several critical factors:

App Environment: High temp, high humidity or when the get bristles are exposed to harsh corrosive substances special brush with resistant properties

Keep in mind the amount of current and voltage: obviously you don't want them to pop prematurely. The brush needs to handle whatever rated amperage without being too hot when finished!

Speed: The speed at which the dynamo rotates affects what brush material and design to use in order for effective current transfer.

Commutator/ Slip Ring Profile Compatibility: The brush has to be perfectly within the commutator/slip ring profile to avoid arcing and ensure its consistent functionality.

To avoid unforeseen downtime and expensive repair work, it is wise to keep some checks greeted with the replacement of carbon brushes inside Electrical currentUsing these simple tricks you canAvoid unscheduled downtimes. With friction and electrical erosion over time, brushes wear down naturally causing increased resistance which could damage commutator surface. Increased sparking, decreased output or odd noises are signs that a wear-out of one brush may need replacing. A practical PM schedule can help operators in maintaining peak performance and extending equipment life, while also reducing catastrophic failures.

There are more than 800 types of carbon brushes for various applications that include carbon brushes that are used as starters, carbon brush assemblies, motorbike carbon brushes, dynamo carbon brush and household appliance graphite carbon products. Standard size from full-automatic production line. keep innovating our products according to latest market demand. We will ensure that our clients the max profit from our cooperation.

We have an extensive stock of carbon brushes that are popular to meet B2B demand. We'll deliver small portions from our warehouse. Save your time, just leaveContact me and I will arrange items for you soonest. we have sell in this kind of product to dynamo carbon brush, and Spanish inExcellent cooperation. From logistics to products, safe and speedy.

More than 20 years experience in carbon brush field We're familiar with diverse market requirements complete technical information continuous testing throughout production dynamo carbon brush go to the Every year meet new and old customers maintain a positive contact between one other Timely reply both before and after-sale sincerity manner of doing business to ensure an ongoing relationship

Make your dynamo carbon brush better from every detail, make your productsAwarded in the market. Meanwhile, accordingly to your demand, we adjust the quality to make the products in long time working with good price.