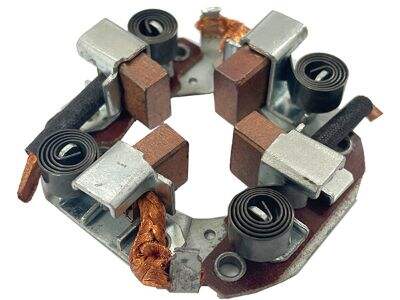

Electric motors consist of multiple components, and motor brush holders are one of them. They allow the motor to run smoothly and efficiently. The other part that could potentially trap dirt is the brush holder — if the design is not right, the motor itself might not be able to perform too. Motor brush holder design and importance Let’s take a closer look at motor brush holder designs and their importance.

Motor Brush Holder Designs: Why They Make a Difference

There are a lot of types of electric motors, including AC indirect motors, AC synchronous motors, stepper motors, and other complex motors, and this also involves various designs of the motors including the motor brush holder. They are the brushes that transmit electricity to the motor’s armature. If the brushes do not touch the armature properly due to a bad design of the brush holder, the motor will work poorly.

Motor Brush Holder, its Main Components

Motor brush holders consist of several main components that work together to ensure proper brush operation. These parts are the holder body, tension springs and brush arms. The holder body grips the brushes and provides support to the brushes. The tension springs hold the brushes in position. Brush arms are the wires that connect the brushes to the motor’s electric system.

How Will Designs Impact Motor Performance

Various designs of brush holders affect the operation of a motor. First and foremost, a solid holder body can prevent the brushes from shaking or moving during motor operation so as to improve motor performance. And quality springs keep constant pressure on the brushes so they maintain contact with the armature.

Stringers Decision Making Features for Good Brush Holder

When finding brush holder designs, it might be best to consider features that can improve their effectiveness. These include the qualities of the materials, the durability of the design and ease of maintenance. Quality materials make the brush holder endure constant use, and a stout design means less repairs. Easy cleaning helps also extend the brush holder and motor life.

Reducing Motor Losses With New Brush Holder Configurations

Brush holder designs can help improve motors performance. For instance, DL’s brush holders use special materials that roles friction and wear, which leads to low energy loss and better performance. They even come equipped with unique design features, such as adjustable tension springs, that allow you to tailor them to individual mechanical requirements, for enhanced running efficiency as a result.

Require a motor brush holder that not only works well but also one that ensures to meet the requirements of the motors well. We can improve electric motor efficiency and lifetime, by studying the reason why these designs matter, reviewing the primary components, checking in features, and innovative ideas for performance enhancement. Select DL's quality brush holders to keep your motor running smoothly and efficiently for years.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BN

BN