Aunque para mí es divertido leer sobre la mayoría de los temas relacionados con motores, entiendo que tal vez no sea el caso para ti, pero aquí hay algunos puntos donde los usuarios de motores encuentran esta información importante.

Las brochas de motor son los héroes silenciosos cuando se trata de lograr una operación eficiente de tu equipo eléctrico. Estos componentes de gran importancia desempeñan un papel vital en la transferencia de electricidad de una sección del motor a otra, lo que permite que tu maquinaria funcione suavemente. Por eso, en este artículo hemos decidido escribir un poco más sobre el mundo de las brochas de motor: su importancia, cuidado y cómo pueden impactar en la vida útil general de tu maquinaria.

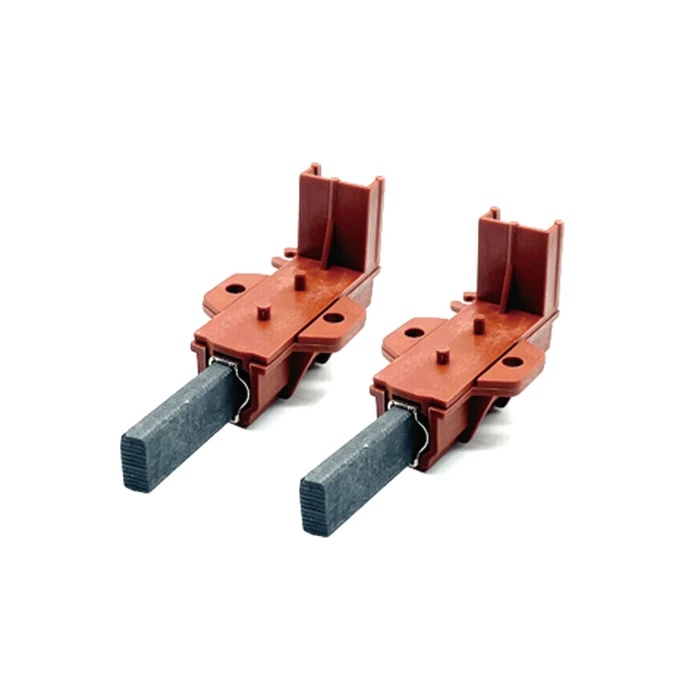

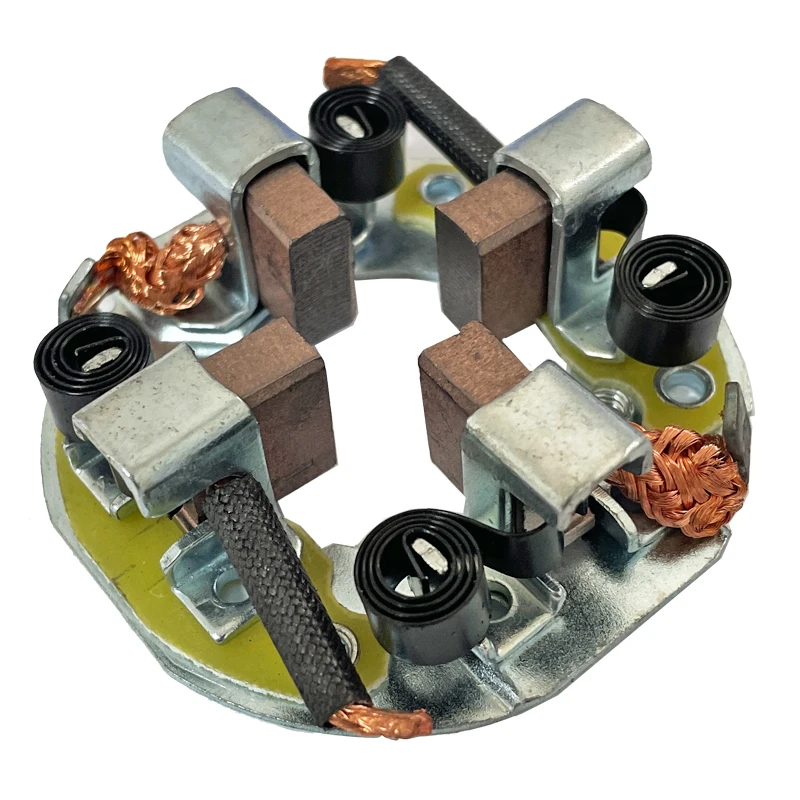

Cepillos para Motores Los cepillos para motores conectan la fuente de alimentación con el motor rotativo, por lo que son necesarios para el funcionamiento del motor. Cepillos para Motores Desgastados pueden aumentar la resistencia eléctrica junto con otros problemas como chispas, sobrecalentamiento y causar daños finales al motor. Esto puede resultar en una menor producción, velocidades más lentas del motor y una reducción en la salida de potencia, lo que llevará al peligro de la máquina. Asegurarse de que los cepillos de su motor estén en perfecto estado de funcionamiento, así como reemplazarlos cuando se hayan agotado, es esencial si no desea pagar más por el mantenimiento que el costo original de su equipo y asegurar su rendimiento óptimo.

Si es aplicable, inspecciones de cepillos, mantenimiento y/o reemplazo para aumentar la vida útil del equipo

Cuidar de tu equipo significa limpiar las cerdas del motor con regularidad. El soporte de las cerdas está propenso a acumular suciedad y residuos, lo que hace que las cerdas se desgasten más rápido. Limpiar tu refrigerador cada cuatro a seis meses (dependiendo del uso) también te ayudará a evitar que atraiga moscas de la fruta. Desatorilla el soporte de las cerdas y limpia ambos componentes, así como el área de contacto de cobre de polvo o acumulación de carbono. Reemplaza inmediatamente las cerdas desgastadas con marcas que coincidan con las especificaciones de tu equipo para un rendimiento óptimo.

Es muy importante seleccionar cepillos para motores específicamente, como los utilizados en túneles de lavado de autos, porque la durabilidad y el rendimiento de su equipo dependen en gran medida de ellos. Los cepillos baratos también pueden resultar en un equipo con un rendimiento inferior, que necesitará ser reemplazado con más frecuencia, lo cual terminará costándole mucho dinero a largo plazo. Por el contrario, los buenos fabricantes tomarán grandes precauciones al construir un cepillo calificado para altas temperaturas y corrientes eléctricas elevadas, lo que proporcionará una vida significativamente más prolongada y evitará desgastes mayores. Aunque es cierto que los cepillos de mayor calidad pueden ser inicialmente más caros, esto se traducirá en un costo neto menor una vez que tenga en cuenta todos los ahorros generados por la reducción del desgaste del equipo.

Es importante conocer los síntomas del desgaste de las brochas del motor antes de que puedan causar otros problemas en su equipo. Demasiadas chispas, demasiado calor o una salida de voltios reducida e incluso un olor a quemado son señales de que necesita cambiar las brochas. Si nota alguno de estos síntomas, inspeccione las brochas en busca de desgaste o daños y reemplácelas según sea necesario para evitar problemas en el futuro.

Elegir las brochas de motor adecuadas para tu mercancía de ventolín sin receta es crucial para un buen funcionamiento. Existen diferentes tipos de brochas dependiendo del tipo de aplicación (carbono, grafito, cobre o plata). Las brochas de carbono se utilizan típicamente en electrodomésticos donde solo se requieren bajos voltajes y corrientes, mientras que la estabilidad térmica del grafito lo convierte en otra opción popular para usos a altas temperaturas. Las brochas de cobre son duraderas y perfectas para aplicaciones de alta corriente, mientras que las brochas de plata funcionan bien bajo potencia intensa y cargas rápidas. Para aplicaciones específicas, debes consultar el manual de tu equipo o un especialista en el campo para determinar qué brocha de motor es adecuada.

El punto es que las brochas de motor son esenciales ya que desempeñan un papel crucial en mantener funcionando adecuadamente y por más tiempo tu equipo eléctrico. Tu equipo funcionará de manera más eficiente, y puedes evitar que se dañen o necesiten reparaciones costosas con demasiada frecuencia si limpias regularmente tus brochas y no usas reemplazos baratos. (Por lo tanto, invertir en las brochas de motor correctas es una de las mejores decisiones que puedes tomar.)

Hacemos que el producto sea más efectivo en todos los aspectos, haciendo que sus productos con brochas de motor sean líderes en el mercado. Al mismo tiempo, de acuerdo con su demanda, ajustamos la calidad para que los productos funcionen durante mucho tiempo a un buen precio.

Para satisfacer las necesidades de los clientes B2B, mantenemos existencias de brochas de motor de las brochas de carbón más solicitadas. Esto te permite recibir las brochas a tiempo. Te enviaremos pequeñas cantidades desde nuestro almacén. No pierdas tiempo, simplemente deja un mensaje, te enviaré los artículos lo antes posible. Hemos vendido este tipo de producto a Alemania y España con una excelente cooperación. Desde la logística hasta los productos, todo es seguro y rápido.

Existen más de 800 tipos diferentes de cepillos de carbón adecuados para diversas aplicaciones, incluidos los cepillos de carbón que se utilizan como arrancadores, ensamblajes de cepillos de carbón, cepillos de carbón para motocicletas, cepillos de carbón para herramientas eléctricas y productos de grafito para electrodomésticos. Tamaño estándar desde línea de producción totalmente automática. Seguimos actualizando nuestros productos para satisfacer las demandas del mercado actual. Para asegurar que nuestro cepillo de motor maximice las ganancias para nuestros clientes.

Más de 20 años de experiencia en el campo de los cepillos de carbón. Estamos familiarizados con diversas demandas del mercado, información técnica completa, pruebas de calidad de cepillos de motores, control de calidad, visitamos la exposición cada año, conocemos a clientes nuevos y antiguos, mantenemos un contacto positivo entre nosotros. Respuesta oportuna antes y después de la venta, sinceridad en el método de negocio para asegurar una cooperación a largo plazo.