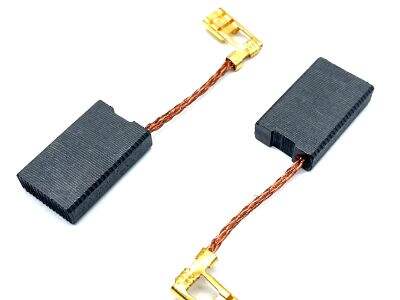

Our necessity for electric motors is very strong. They are found in many areas, such as our homes, schools, and factories. We depend on it to accomplish countless things like operate our appliances, drive machinery, and turn on our lights. Ever wondered what the key is that makes electric motors work? They are in fact small components known by the name of brushes. These brushes supply power to the motor and run it. With the ever-growing use of electric motors around the world, it is necessary to find improved ways faster to assemble these brushes. This is where the new device from DL comes in—enter the Automated Electric Motor Brush Assembly!

What A New Machine Results in More Brushes Made Faster and Money Saved

The new machine from DL is created to be pretty fast and still offers high-accuracy. In this way, it allows the manufacturing of motor brushes like Berus Karbon Pemula in far less time than earlier. The machine also saves worker expenditure on working with the few materials that it receives. The human-like brush making part of the machine: Since this works so nicely, you can make a lot more brushes while making fewer mistakes. It is both helps the factory become more productive and save money, allowing basically an all around effective process.

The Advantages of Making Brushes Using the Machine

This is that the machine of DL makes the brushes like berus motor elektrik very accurately and in same manner each and every time. This is critical in manufacturing. It is easy to use, so that employees can quickly get used to this machine. It can work, literally all day and night long without ever making a mistake, which is huge. The brushes produced are perfect every time because it works so effectively, making sure they meet all the necessary virtues.

Here is how the new machine helps workers and saves money.

Earlier the process of making brushes took many labours and hours to keep a tab on the quality at regular intervals. The result was that maintaining quality became a struggle, and price increased in many cases. It's a much easier process with DL's new machine. It facilitates a faster operation and it demands a fewer number of workers to function what makes the factory save money with labour costs. This frees up workers to perform other tasks, rather than the dull repetitive assembly work, which improves the quality of brushes as a whole.

What the New Machine Does to Make Work Safer

The machine used by DL for this output also has an important side benefit, it makes work safer for everyone involved. Previously, menial cutting and nailing work was required for workers. The result of these activities is that the majority accidents and injury. The machine now handles these hazardous duties which is good for the health of workers and the less accidents on the factory floor. Moreover, a device that created a workload of hard and tiring physical burdens on the workers, who had to do these tasks manually.

Why You Should Invest in the New Machine

By purchasing DL machine To invest in the future of any factory This machine will enable a large number of brushes like replacing carbon brushes to be produced at the same time, so it should save money in the end. It fixes errors by utilizing the automation technology, reducing waste and ultimately creating more brushes in general. This machine is used by factories to create premium quality products in the minimum time. Why this works nicely is that its a high ceiling from zaman on which you can earn your profits over time.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BN

BN