A carbon brush drill is one of those tools with tons of applications in multiple jobs across industries. That describes the bits that are useful for drilling, or for mixing several types of materials with one bit, and even cutting. In these drills, the carbon brush is an indispensable element that contributes to its smooth operation. Oftentimes, the design and type of material is dependent on how well a drill will work from start to finish. DL is a well known brand– they understand what brush to use for which purpose that gives the best final result.

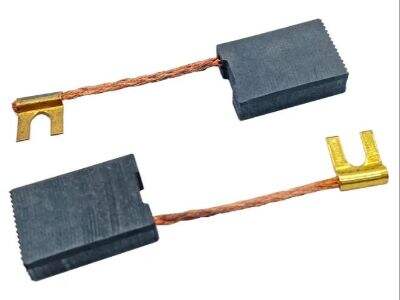

They are made from material such as graphite, copper, and plastic.

None of these materials has no use in the grand scheme of things. This brush has graphite to ensure the electricity transmission by maintaining connectivity and it is built with copper to make it strong. The resin glues everything together and that maintains the brush shape. All Together, these materials together create the best possible case to make a brush carry some kind of an electric charge that lasts longer than in any other material. DL Brushs adopt best and high quality materials to produce our Product that make the brushes with hard, flexibility and durability performance in different bath.

Besides, the style of the brush matters.

Force of brushThe size and the type determine how much force it can exert on commutator. The commutator, the supposed thing to be in the drill and turn to help things make power- The drill will act different if the brush is turning too big, or just the right size but not shaped right likely gift with ensure flow like this was. This is the product of good engineering you see DL knows damn well they are going to need a better brush for their guys that the ones already out there, at least it turns out to be cheaper.

Working by pushing against the commutator Similar to a carbon brush, one purpose of the Starter Carbon Brush is to create that flow required energy for your drill. It is important, however, to make sure you do not use too much pressure. If the pressure is not sufficient, it may prevent the brush from making full contact with the commutator lead to poor performance. On the other side, if pressure is too high it also damages not only brush but commutator(relativly). This is why it is paramount that you be able to manage the pressure.

DL recommends you to adjust the springs only using a special tool as they are specific spring tension system.

This is the part where users will be able to change out how much carbon brush pressure on the commutator to dial in for best performance. For the brush to work correctly, it must be tensioned and reset quite often. The correct pressure will not only help you save your equipment but also helps keep your drill going smoothly.

After all, the secret to having a long-life drill is proper care. Lubrication and cooling techniques also play a vital role in maintenance. DL note: Brush lubricant for brush and commutator is HIGHLY RECOMMENDED. This translates into suboptimal friction causing heat ultimately generation destructive. In addition to lubrication, however, cooling methods like air or water cooling are also very effective. The process of cooling is to keep the drill from overheating when in operation; this is positive since a hot drill would break down more and lower power.

As with all drills

Carbon brush step drill bits should be checked and replaced as needed even when maintained well. DL advises users to keep an eye on the carbons for that reason, to ensure they wear uniformly as well as, additionally, that the commutator is not harmed. The drill brush replacement process of the manufacturer is a simple maneuver, but it significantly improves its work. They come with replaceable brush holders that are conveniently located and easy to change when necessary, so the replacement process is simple. Using starter carbon brush drills and other professional gear can be very dangerous if not operated or handled safely as proper training and safety protocols are a must. Training teaches operators how they can perform their role as efficiently and safely as possible. Any user must have exact guidance before using it to avoid injury and equipment harm. We obviously cannot forget the training of the operator or that all safety guidelines and precautions provided by the DL company upon acquiring one must be respected. It provides mounting proof for protocols as long as they provide the highest efficiencies not leading to dysfunction and a safe environment for all parties.

To some is, DL delivers Relift in using contains carbon brush drills appropriate all in all. The DL brand provides these features in its product, and if a user takes special care of it by implementing design of carbon brush, applying proper pressure, using lubrication with suitable techniques for cooling and cooling methods such as individual replacement of brushes, given training and safety precautions can guide the machine correctly maintenance to ensure that users do not experience any problems over multiple years make DL drills one hundred percent essential tool for users.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BN

BN